Product

Knowledge

Spring washer also known as a lock washer or a split washer, is a type of washer used in mechanical and industrial applications. It is designed to provide additional security and prevent the loosening of fasteners (such as nuts and bolts) due to vibrations, thermal expansion and contraction, or other factors. Spring washers are commonly used to maintain tension in a fastened joint and reduce the risk of self-loosening. There are several types of spring washers, each with its unique design and application. Here are some common types:

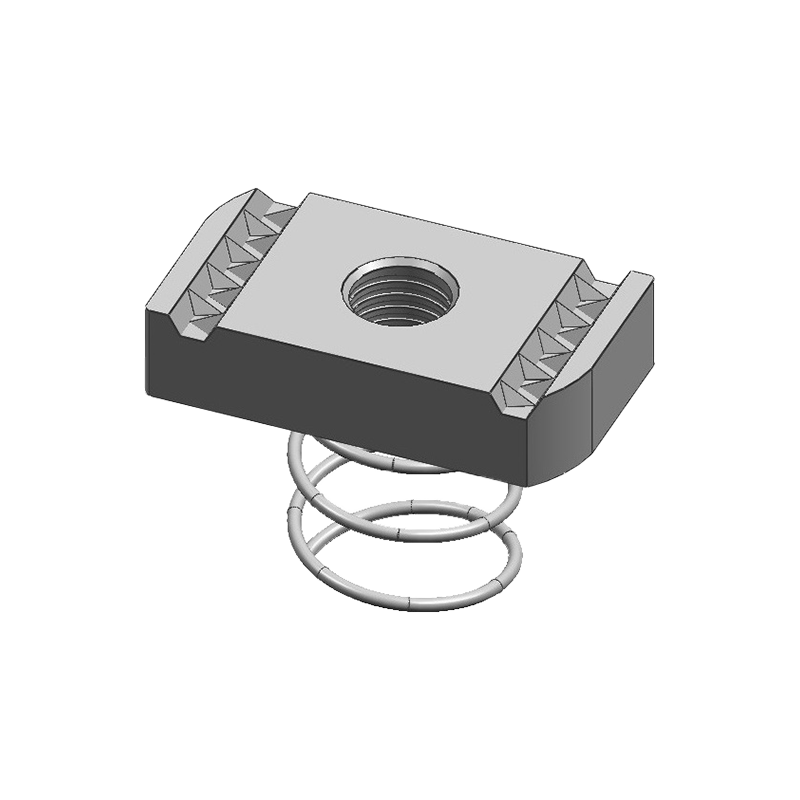

Split Washer: This is the most basic type of spring washer. It has a split or cut in the shape of a ring or helix. When compressed between the nut and the workpiece, it exerts tension to prevent the nut from backing out.

Wave Washer: Wave washers have a wavy or curvy shape. They are used to provide a cushioning effect, reduce vibrations, and compensate for slight misalignments in the fastened joint.

Belleville Washer: Belleville washers, also known as conical spring washers, have a conical shape. They are designed to provide high spring loads in tight spaces and maintain tension over a range of loads and temperatures.

Serrated Washer: Serrated washers have serrations on one or both sides, which bite into the surface of the fastened material and the nut, creating resistance against loosening.

Toothed Washer: Toothed washers have teeth or prongs around their inner and outer edges. These teeth bite into the fastener and the material to prevent self-loosening.

Common uses of spring washers include:

Automotive and machinery assembly to prevent nuts and bolts from coming loose due to vibrations.

Construction and building applications to secure structural components.

Heavy machinery and equipment where maintaining the integrity of fastened joints is essential.

Electrical and electronic equipment to prevent connections from loosening.

Plumbing applications to secure pipes and fittings.

It's important to note that while spring washers can be effective in preventing self-loosening, they may not be suitable for all applications. In some cases, other fastening methods, such as using thread-locking compounds or torque-limiting devices, may be more appropriate. Proper installation and selection of the right spring washer type and size are essential to ensure their effectiveness in a given application.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)