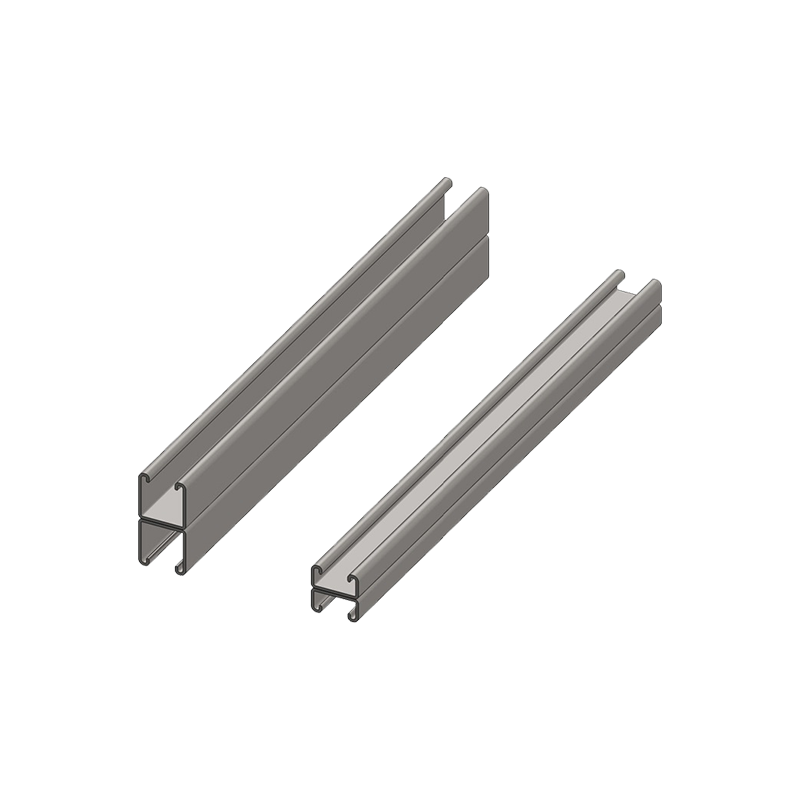

The size and form of

engineering channel steel are important aspects that have an impact on its structural performance and load-bearing capacity. Engineering channels are generally available in standardized styles and sizes, and their selection relies upon at the particular requirements of the structural or creation project. Here are a few concerns regarding the dimensions and shape of engineering channel metal:

Dimensions:

Channels are characterised by way of their dimensions, which include top (h), width (b), and thickness (t). Standard sizes are to be had, however the dimensions can range primarily based on the specific application and layout necessities.

Profile:

Channels are available unique profiles, inclusive of C-shapes, U-shapes, and miscellaneous shapes. The choice of profile depends at the structural desires of the challenge.

Orientation:

Channels may be orientated vertically (C-shape) or horizontally (U-form). The orientation is chosen primarily based on the structural requirements and the direction of loads.

Standard Sizes:

Common standard sizes for engineering channel metallic are installed with the aid of industry standards and specifications. These sizes are generally expressed in terms of the height, width, and thickness of the channel. For instance, a "C8x13.75" shows a C-shaped channel with a nominal peak of eight inches and a weight of thirteen.Seventy five kilos in keeping with foot.

Material Thickness:

The thickness of the channel steel is a critical thing in figuring out its load-bearing capacity. Thicker channels usually have better load-bearing capacities but may also be heavier.

Weight in step with Unit Length:

The weight in keeping with unit duration of the channel is an crucial consideration for transportation, dealing with, and installation. It's expressed in kilos or kilograms consistent with foot or meter.

Design Codes and Standards:

The selection of channel size and shape is frequently guided by design codes and standards relevant to the particular utility or industry. These codes offer hints for selecting appropriate sizes based totally on elements like structural loads and span.

Structural Analysis:

Structural engineers carry out certain analysis to determine the best length and form of channel steel for a specific software. This evaluation considers elements such as the span, loading situations, fabric homes, and protection factors.

Availability:

The availability of popular sizes in the market may have an effect on the choice. Common sizes are with ease to be had, but custom sizes can be manufactured if wanted.

Application-Specific Requirements:

The requirements of the unique utility, whether or not it is in building production, infrastructure, or business tasks, play a extensive position in determining the scale and form of the channel metallic.

It's critical to work with structural engineers and cling to relevant layout codes and standards whilst selecting the scale and form of engineering channel metallic. These professionals can perform the important calculations to make sure that the chosen channels meet the structural and protection requirements of the project.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch