Industry Knowledge Development

Engineering bolts

Engineering bolts are a type of fastener that is used to hold two or more objects together.They are typically made of strong,corrosion-resistant materials such as steel or stainless steel,and are designed to withstand high levels of tension and torque.

Engineering bolts come in a variety of sizes and styles, including hex bolts,carriage bolts,and socket head cap screws,and are used in a wide range of applications,including construction,automotive,and industrial equipment.

What are the advantages of engineering bolts

Engineering bolts are designed and manufactured to meet specific technical and performance requirements.Some advantages of

engineering bolts include:High strength:

Engineering bolts are made from high strength materials such as alloy steels and are designed to withstand high levels of stress and tension.Dimensional accuracy:

Engineering bolts are carefully manufactured to very tight tolerances,ensuring that they fit properly and function as intended.Corrosion resistance:Some

engineering bolts are coated or treated to resist corrosion,making them suitable for use in outdoor or harsh environments.Customization:

Engineering bolts can be customized to meet specific requirements, such as specific thread patterns or head styles.Versatility:

Engineering bolts are used in a wide variety of applications and industries,including construction,automotive,aerospace,and manufacturing.Cost-effective:In many cases,

engineering bolts can be a more cost-effective solution than other fasteners,such as welds,due to their ease of installation and ability to be reused.

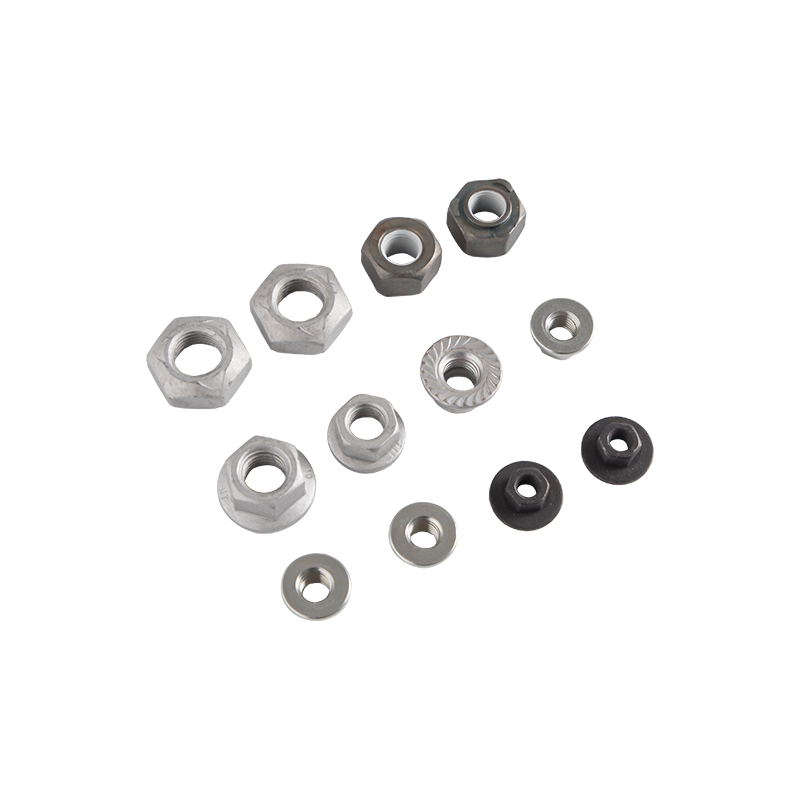

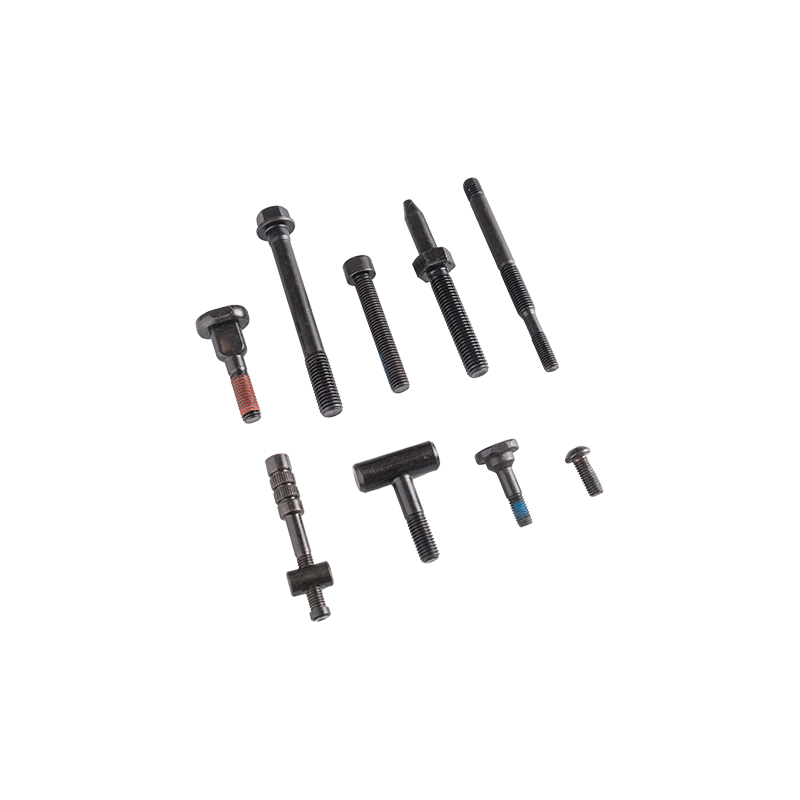

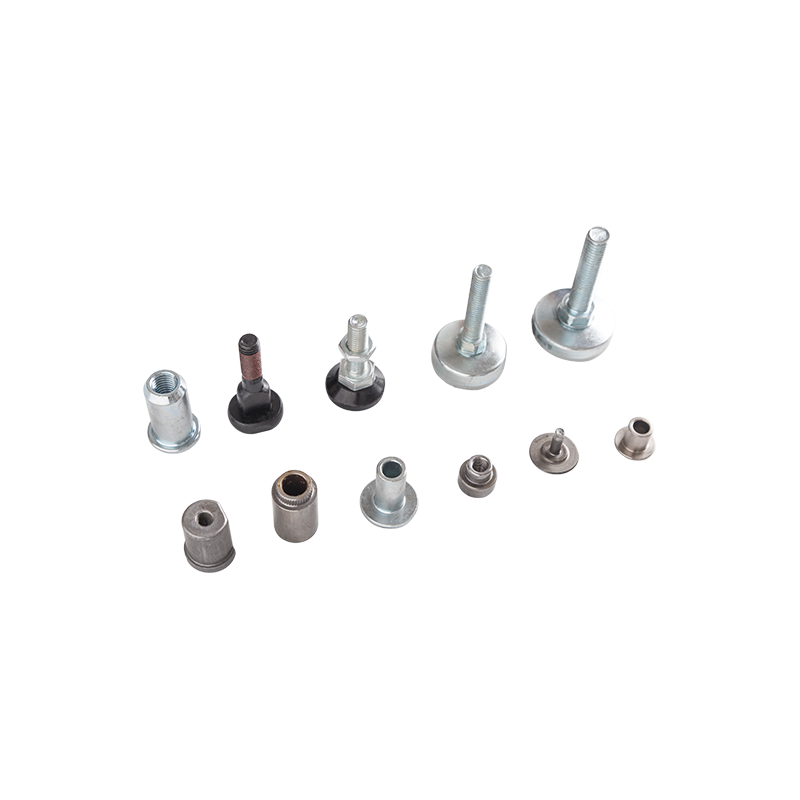

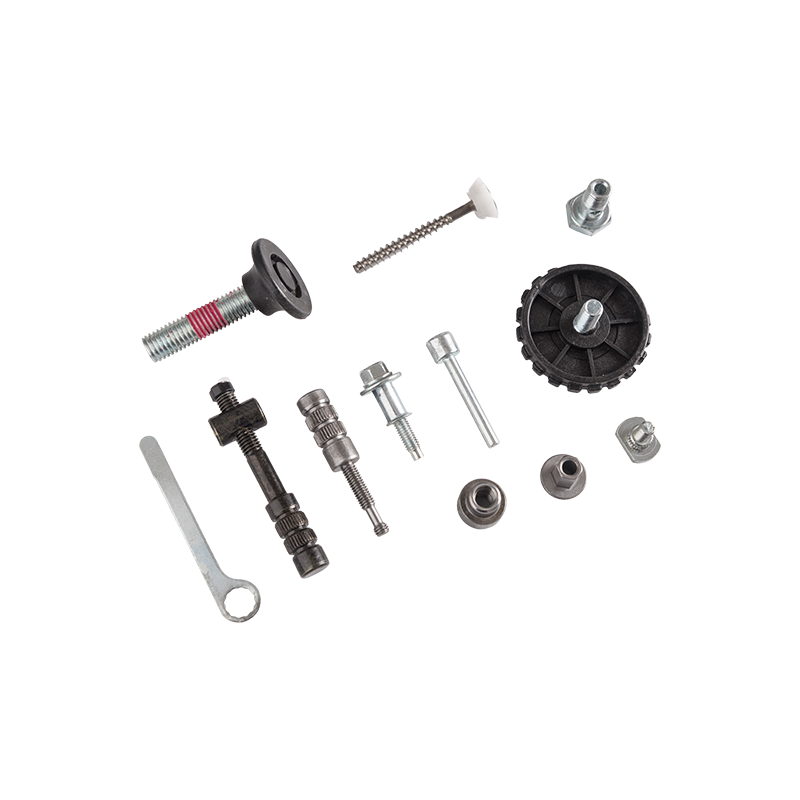

What are the types of engineering bolts

There are several types of

engineering bolts,including:Hex bolts:These bolts have a hexagonal head and are used in construction and other applications where a strong,reliable fastener is needed.Carriage bolts:These bolts have a smooth,rounded head with a square neck that prevents them from turning when tightened.They are commonly used in wood applications.Lag bolts:These bolts have a hexagonal head and a coarse thread.They are used for fastening wood to wood or wood to other materials.Structural bolts:These are heavy-duty bolts used in the construction of buildings and other structures.They have a larger diameter and are designed to withstand high levels of stress.Machine screws:These bolts have a small diameter and are used to fasten small parts together.They are commonly used in the manufacturing of electronics and other small devices.Socket screws:These bolts have a socket in the head that allows them to be tightened and loosened with a socket wrench.They are often used in applications where a smooth,low-profile head is needed.Self-tapping screws:These screws have a thread that allows them to create their own hole as they are tightened into a material.They are commonly used in the construction and automotive industries.

What are the characteristics of engineering bolts

Engineering bolts are mechanical fasteners that are used to hold two or more objects together.They are typically made from a strong, hard material such as steel or titanium,and are designed to withstand high loads and pressures.There are many different types of

engineering bolts,each with its own specific performance characteristics.Some common performance characteristics of

engineering bolts include:Tensile strength:The maximum load that a bolt can withstand before it breaks.This is typically measured in pounds per square inch (psi) or mega pascals (MPa).Yield strength:The point at which a bolt begins to deform permanently under a load.This is typically measured in psi or MPa.Shear strength:The maximum load that a bolt can withstand when subjected to shear forces (forces acting parallel to the cross-section of the bolt).This is typically measured in psi or MPa.Torque:The rotational force required to tighten a bolt to a specified level of tension.This is typically measured in inch-pounds (in-lb) or Newton meters (Nm).Corrosion resistance:The ability of a bolt to resist corrosion,or the degradation of its properties due to chemical reactions with its environment.Fatigue strength:The ability of a bolt to withstand repeated loading and unloading without failing.This is typically measured in cycles to failure.Temperature resistance:The ability of a bolt to maintain its strength and other performance characteristics at high temperatures.Hardness:The resistance of a material to deformation, indentation,or scratching.This is typically measured using a hardness scale such as the Rockwell scale.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch