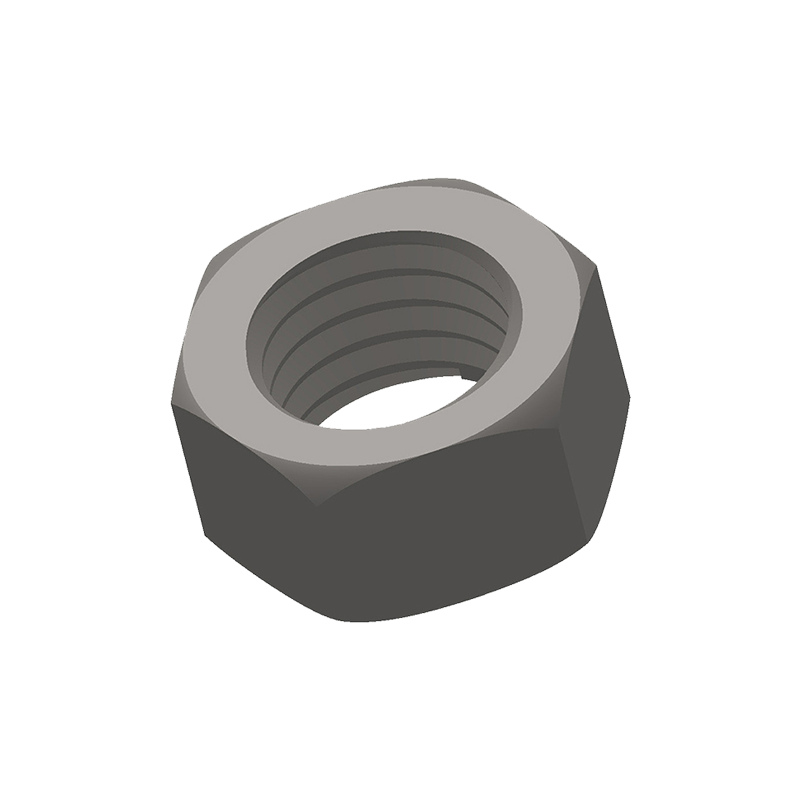

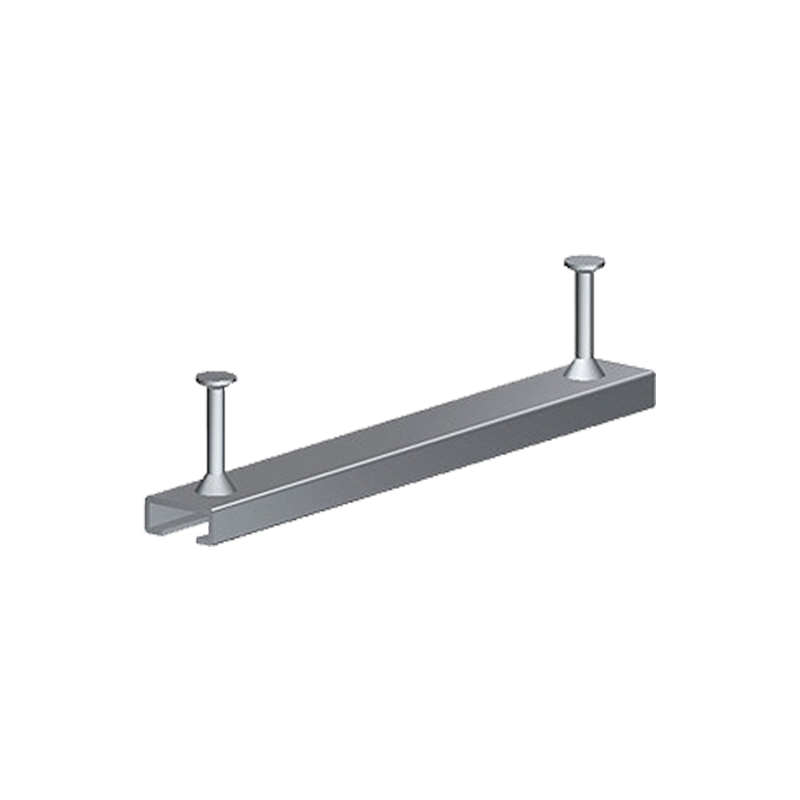

Engineering Channel Steel is a form of metal strip that has been shaped into a U, J, or C shape to be used in several industrial applications. This form of metal has many benefits and is available in various sizes to suit specific needs. Its unique design is what sets it apart from other types of steel, making it perfect for structural applications. Its rigidity is greater than that of flat steel stock, and it can also provide support for heavier equipment and machinery.

The process by which a steel channel is created is known as roll forming. This process involves feeding the strip through a series of rollers, or supports, that distort the steel until it takes on its final shape and size. This can be accomplished by using a computer-controlled system, which controls the positioning and direction of the supporting rollers. The strip is then cut to its desired length and may be galvanized or welded to create a finished product.

.png)

There are a variety of different kinds of metal channels that can be made using the roll-forming process. Some of these are named for their shape and others for the types of work they can be used for. For example, a metal U channel is named for its "U" shape and is most often used as a supporting structure. It can be used as a beam in a building, to add strength to wood beams during remodeling, or to increase the overall height of a wall or roof.

Another common kind of metal channel is the stainless steel C channel, which is named for its shape and used as a support for structures that are exposed to the elements. This kind of steel is highly resistant to corrosion, which makes it ideal for outdoor use and other applications where the steel might be prone to water or air damage. It is also less expensive than other types of steel.

Steel channel is also used to create frames for doors and windows in both wood and metal-framed buildings. The steel is strong enough to resist dents and other damage and provides a more stable frame for the window or door than wood can.

In addition to being extremely durable and versatile, these steel channels are also lightweight. This makes them easy to handle and install in a construction project. They can be used to reinforce concrete beams, create supports for machinery and heavy equipment, or make frames for walls. They are also often used to absorb sound by being placed between the walls of plasterboard buildings, where they can muffle vibrations caused by noise on either side. They can even be drilled or bolted into place to hold electrical wiring and other connections. The possibilities for the use of this type of steel are endless, as it is a very tough and long-lasting material.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)

.png)