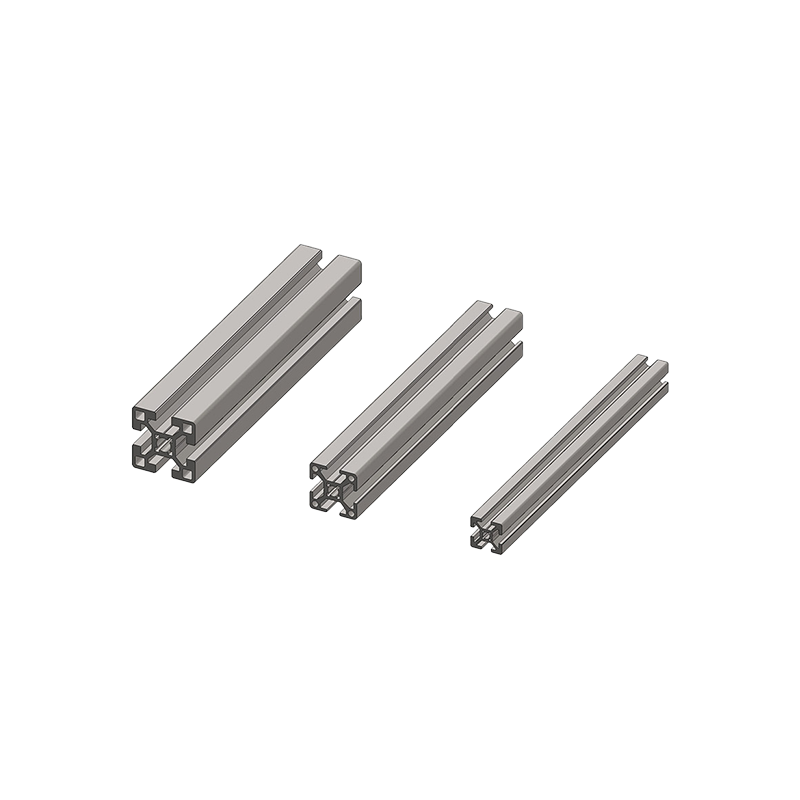

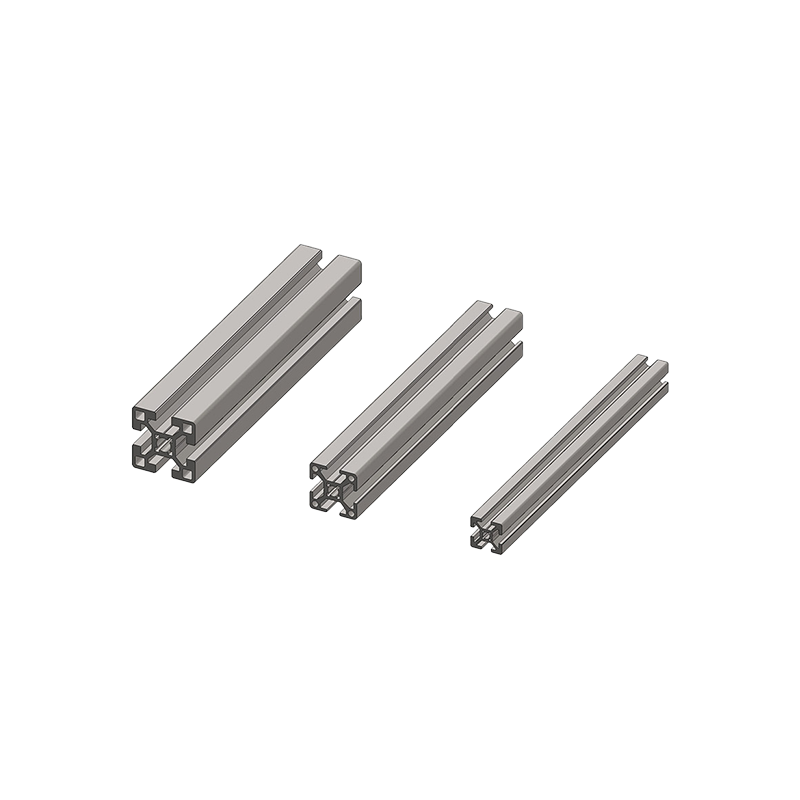

Regular Inspection: Conduct routine inspections of the channel steel to check for any signs of damage, corrosion, or structural issues. Look for cracks, rust, or deformation, as these can weaken the steel and compromise its load-bearing capacity.

Cleaning: Keep the channel steel clean and free from dirt, debris, and any corrosive substances. Regularly wash the steel with clean water and mild soap to remove dust and contaminants. For stubborn dirt or rust, use a non-abrasive cleaner or rust remover.

Corrosion Protection: Channel steel, especially if used outdoors or in corrosive environments, is susceptible to rust and corrosion. Apply a protective coating, such as paint or galvanization, to prevent corrosion and extend the steel's lifespan. Make sure to follow the manufacturer's recommendations for coating materials and application.

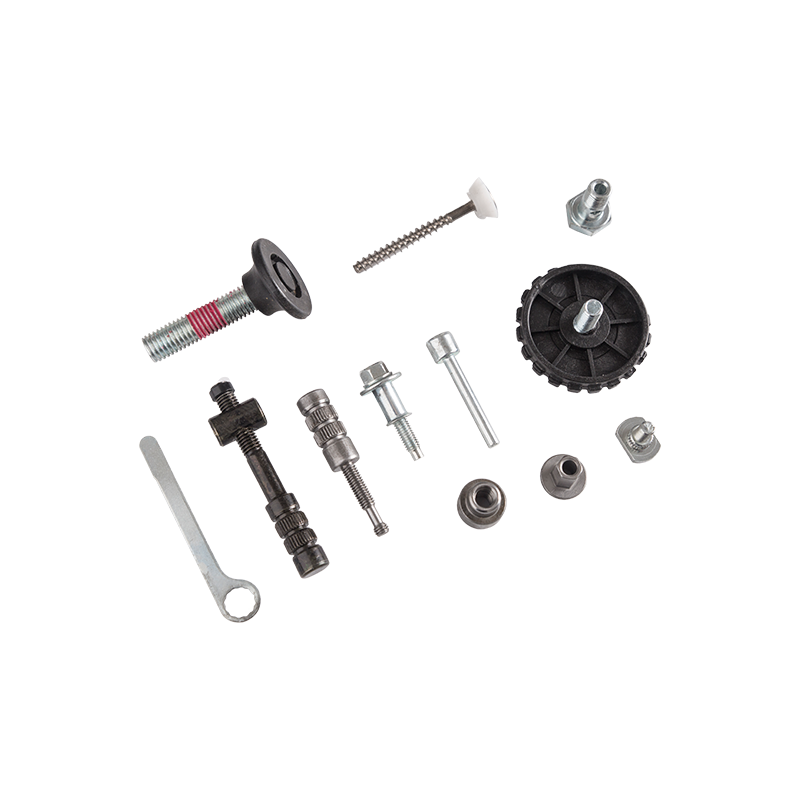

Lubrication: If the channel steel has moving parts, such as hinges or joints, apply appropriate lubrication to ensure smooth operation and reduce friction, which can lead to wear and tear.

Preventing Impact Damage: Take precautions to avoid impact damage to the channel steel. This can be achieved by installing protective barriers or bollards around critical areas to prevent accidental collisions with vehicles or machinery.

Monitoring Load Limits: Be aware of the load limits of the channel steel and avoid exceeding them. Overloading the steel can lead to structural failures and compromise safety.

Addressing Repairs Promptly: If you notice any signs of damage or wear during inspections, address them promptly. Small issues can escalate and cause more significant problems if left unattended.

Consider Environmental Factors: If the

channel steel is exposed to extreme weather conditions, such as saltwater or high humidity, take extra precautions to protect it from corrosion. In such cases, you may need to use specialized coatings or materials for increased durability.

Maintain Proper Drainage: Ensure that there is proper drainage around the channel steel to prevent water from pooling and causing corrosion.

Consult with Professionals: If you are unsure about how to properly maintain the channel steel or encounter significant issues, consult with a structural engineer or maintenance professional for guidance and assistance.

By following these maintenance practices, you can help extend the lifespan of engineering channel steel and ensure it continues to perform its intended functions safely and effectively.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)