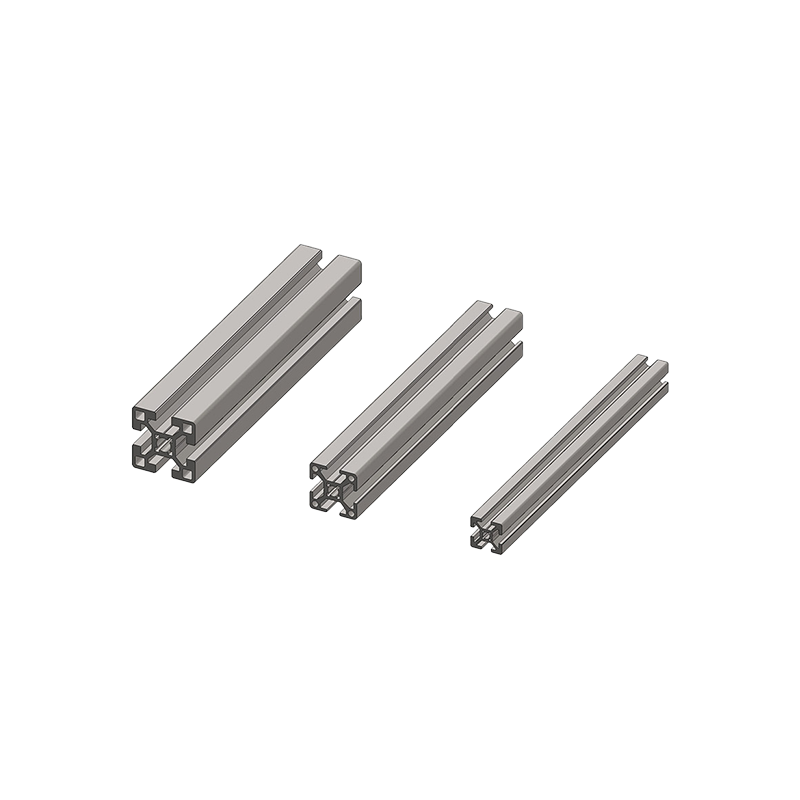

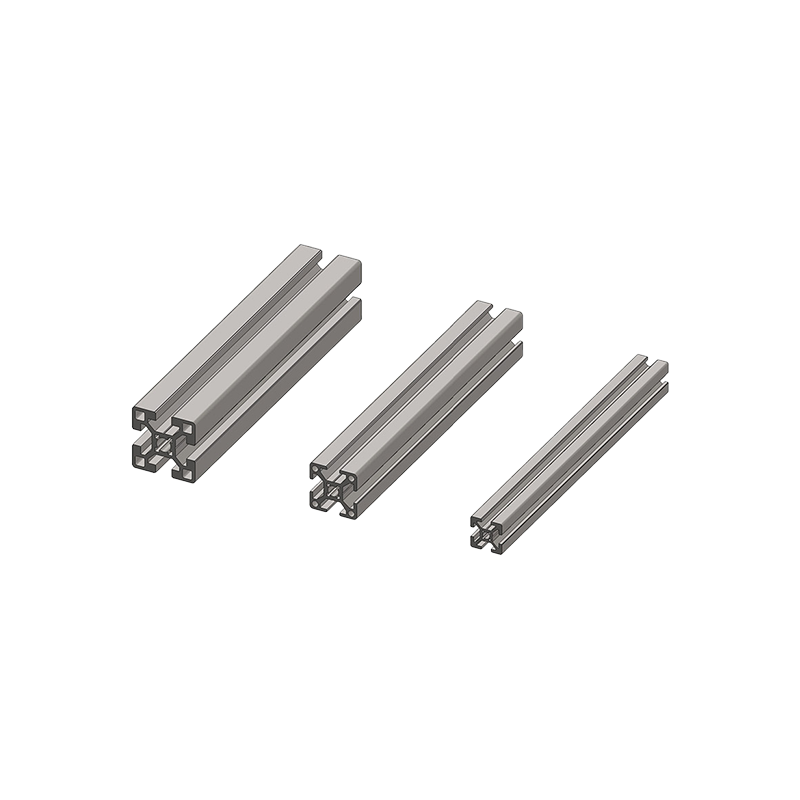

Engineering Channel Steel is a unique type of roll formed metal strip that can be molded into a variety of forms and dimensions. They can be used in various industries. They are particularly popular in building rafters and walls. They can also be used in industrial enclosures.

Damage to these structures can occur through tearing ruptures or corrosion. This can significantly impact their capacity to bear load and elongation.

Steel channel is a type of metal that’s used to support a variety of projects. Its strength, durability, and cost-efficiency make it a popular choice for building frames. It’s also commonly used in metal doors and windows, as well as for piping systems. Metal channels can be made of any type of metal and are often galvanized to ensure corrosion resistance.

To understand the impact of damage on steel channel element properties, experimental tensile tests were performed on 15 specimens. The tests were conducted on a tensile testing machine with a capacity of 1000 kN. The results showed that the relationship between load and elongation is very close for both control and damaged elements.

However, it’s important to note that these results do not imply that the damage has a significant effect on the capacity of the steel channel element. This is because the stresses are redistributed and are not concentrated at one end of the cross-section.

Durability

Steel channels are a great choice for building frames and braces, as well as supports for heavy equipment and machinery. They’re also extremely tough and long-lasting. They are typically fabricated using hot-rolled steel, and they’re often galvanized to increase their durability. This makes them strong, durable, and cost-effective.

Steel channel lintels are highly corrosion-resistant, making them an excellent choice for commercial and residential construction. They are also fire-resistant, which is important in buildings with high safety requirements. In addition, they can be fabricated with different coatings to meet specific architectural needs.

A significant influence on the capacity of steel element structures is the location of damage in their unconnected legs. To investigate this, 15 specimens of channel steel elements with different damage ratios were tested on an axial tensile test machine. The relationship between the load and elongation was measured for each specimen, and the results were then used to predict the residual axial load of each damaged steel element.

Steel channels are an excellent choice for construction projects because they are extremely tough and long-lasting. They are used in building frames and braces and also as supports for a variety of heavy equipment and machines. They are also very thick, allowing them to absorb sound and muffle vibrations.

Metal channels can be made in many different ways, but the most common is roll forming. This process involves placing a sheet of metal between a pair of rollers that bend the metal into the desired shape. This is a cost-effective method that allows for custom dimensions and sizes.

Metal channels are often referred to as “C” channels because of their C-shaped design. However, the term can be used to refer to any type of channel. These structures are commonly found in building projects, and they can be fabricated to fit any specific demand. In addition, these steel structures are durable and highly resistant to corrosion.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)