Engineering Channel Steel and Its Many Uses

Posted by Jiaxing Taigor Machinery Co., Ltd.

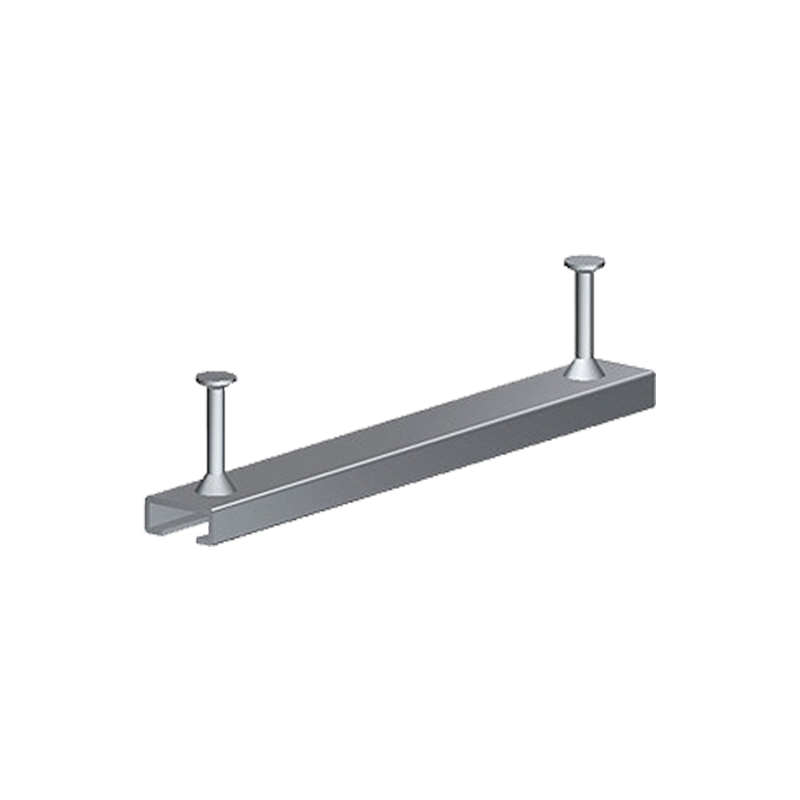

Engineering Channel Steel is a type of metal that has various uses. Its strength and durability make it ideal for use in construction projects that require strong and sturdy supports. The metal can withstand a lot of strain without risking its integrity and can also be easily formed into the desired shapes and sizes. It can be welded to create a strong bond between pieces. It can also resist corrosion and rust.

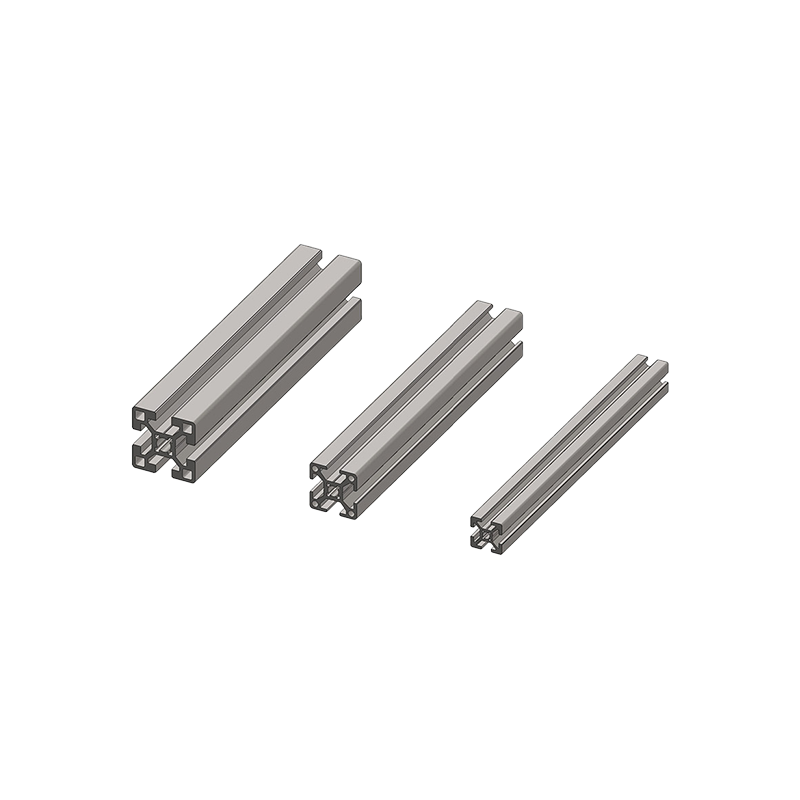

This article will discuss the different types of steel channels and their benefits. It will also explain the differences between them and how to choose the right one for your project. Steel channels are made through a roll forming process that can mold the metal into various channel shapes, depending on the specific application and needs of the user.

Metal channels can come in a variety of forms and sizes, with some having straight backs and others having perpendicular extensions on both sides. Some have holes or perforations to allow for bolting purposes, while other types have a slight ridge to increase rigidity and provide additional support for the structure. The flange thicknesses and widths will vary as well, and they can be sized to accommodate the load-bearing capacity required for the specific application.

Generally, the larger the steel channel, the stronger and more durable it is. However, the exact size of a metal channel is determined by its load-bearing capacity and other criteria, such as span length. It is important to determine the correct size of a steel channel for the specific project and to consult with a structural engineer or a manufacturer’s load tables.

Some of the most common uses for steel channels are in wood-framed buildings. They can be used to strengthen the wooden beams, providing increased sturdiness and rigidity to the entire structure. They can also be used as a means of reinforcement for other structural components, such as girts and joists.

In addition to strengthening wood structures, metal channels are often used in commercial and industrial construction. They can be used to construct secure frames for windows and doors, or as lintels to increase the overall stability of the building. They can be fitted into an opening to create a solid lintel that is much more secure than those constructed from timber. They can also be used to create the frames for commercial fire doors and sub-grade basement doors.

Another benefit of using metal channels is their ability to reduce noise in a room. When they are inserted between the two sides of plasterboard walls, they can help to muff sound waves and vibrations that may be caused by a speaker on either side of the wall. This can be helpful in ensuring that sound does not travel from one room to the other, and can also help prevent excessive sound reverberation. It can be an ideal solution for areas that need to remain quiet and private. In addition to this, they can also be used to prevent noise from outside the room, such as traffic or aircraft.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)