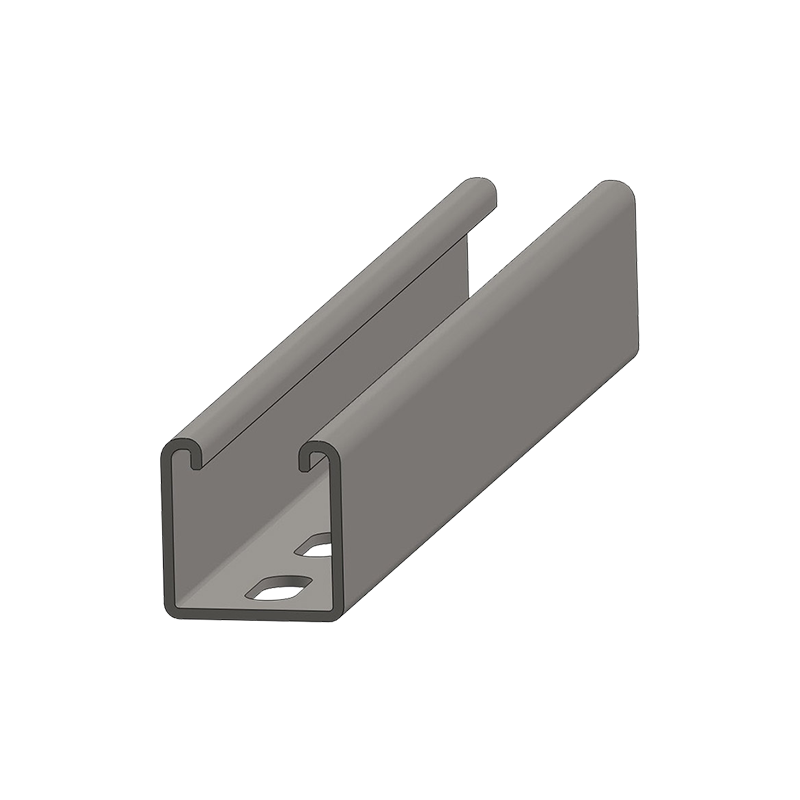

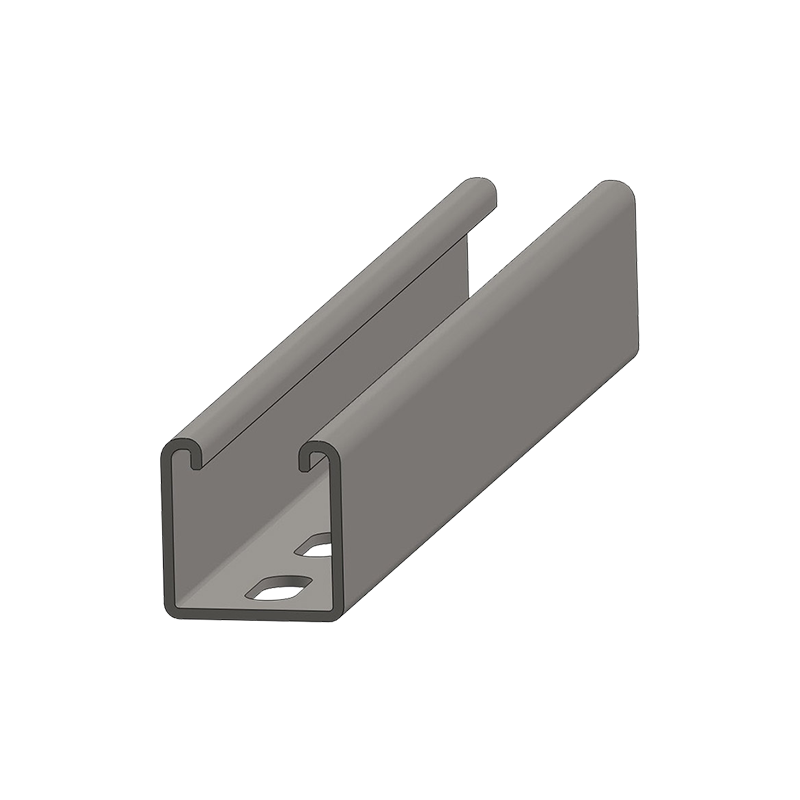

The load-bearing capacity of channel steel depends on several factors, including the type and grade of steel, the dimensions of the channel, the method of support, and the application's specific requirements. Engineers and structural designers calculate load-bearing capacities to ensure the safe and efficient use of

channel steel in various applications. Here are some general considerations regarding the load-bearing capacities of channel steel:

Type and Grade of Steel: Different types and grades of steel have varying load-bearing capacities. High-strength steel will generally have a higher load-bearing capacity than lower-strength steel.

Channel Size and Dimensions: The dimensions of the channel steel, including its depth, width, and thickness (flange and web), play a significant role in determining its load-bearing capacity. Larger and thicker channels can typically carry higher loads.

Orientation of the Channel: Whether the channel is used in its standard orientation (with the flanges vertical) or in a rotated orientation (with the flanges horizontal) can impact its load-bearing capacity.

Support and Connection Methods: The way the channel steel is supported and connected in a structure affects its load-bearing capacity. Properly designed connections and supports are crucial for distributing loads effectively.

Span Length: The distance between supports (span length) is a critical factor in determining the load-bearing capacity. Longer spans generally require larger and stronger channel sections to support the load.

Load Type: Different types of loads, such as dead loads (permanent/static loads like the weight of the structure itself), live loads (dynamic loads due to occupants or movable objects), and wind or seismic loads, have varying effects on load-bearing capacity. Engineers consider these factors in their calculations.

Safety Factors: Engineers apply safety factors to ensure the structural integrity and safety of a design. These factors account for uncertainties in load estimation, material properties, and construction practices.

Local Codes and Standards: Building codes and industry standards provide guidelines and requirements for calculating load-bearing capacities. Structural designs must comply with these codes and standards to ensure safety.

Buckling and Deflection Limits: Engineers also consider factors such as buckling (the tendency of slender sections to fail by bending) and deflection (the amount of bending or sagging) when determining load-bearing capacities.

Dynamic and Impact Loads: In some applications, such as machinery or equipment support structures, dynamic and impact loads need to be considered in addition to static loads.

Load-bearing capacity calculations are complex and involve a combination of analytical methods, mathematical equations, and computer simulations. Engineers and structural designers assess all relevant factors to determine the appropriate channel steel size and configuration to safely support the intended loads for a specific application. It is essential to consult with a qualified structural engineer or designer to ensure that channel steel is used correctly and safely in structural and construction projects.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)