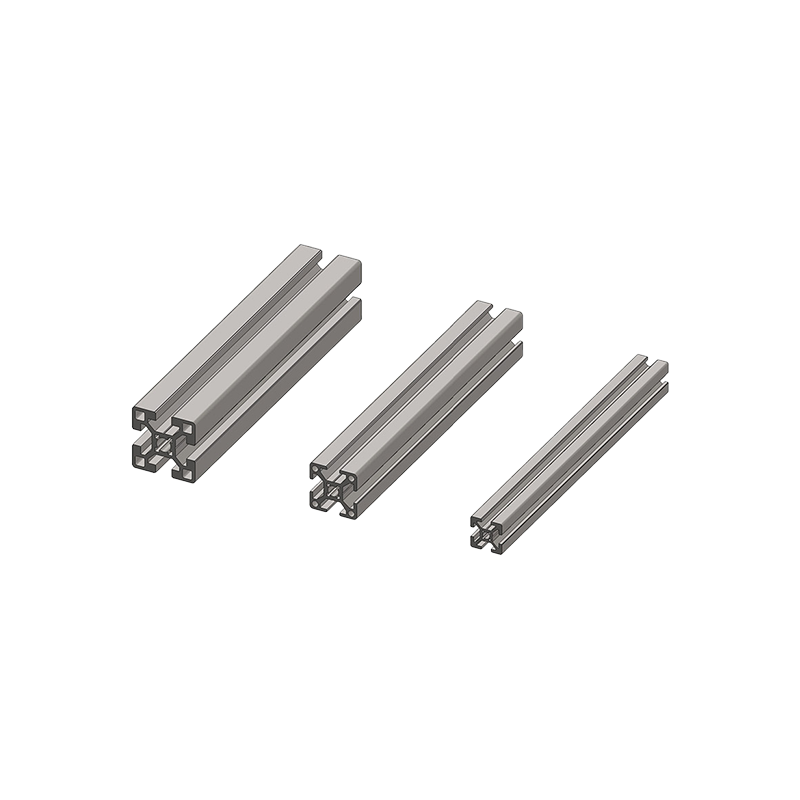

Steel channels are a type of metal that is often used in a variety of industrial applications. They are often made from hot-rolled metal strip, but can also be manufactured through cold forming or welding. They come in a variety of sizes and shapes, and can be made from different types of metals depending on the needs of each application. They are also highly durable and have a number of other mechanical properties that make them ideal for use in many different applications.

.png)

Often used in construction, steel channels can be found in a number of different buildings and structures. They can be a part of a building's frame and braces, or they may be used to support a variety of machines and heavy equipment. Steel channels are extremely strong, which makes them ideal for these types of applications. They are also thick, which helps them to absorb sound and muffle vibrations. They can also be used to provide structural support for wooden beams in a home or other structure, as well as to reinforce the joints of joists in wood-framed walls.

Another common application of steel channels is in retaining wall systems. These systems are designed to contain soil and other materials, but need to be stable and able to withstand loads. Steel channels are perfect for this because they can be used to retain earth and other materials without requiring large amounts of concrete or other forms of heavy foundation. They are also a good choice for bridges, since they can withstand a lot of flex and movement that might damage more rigid I-beams or H-beams.

In the automotive industry, steel channels are used to support the different components of a vehicle, and can even be found in the frame itself. This helps to keep the vehicle stable, and it can even help minimize the impact of minor collisions, which can be damaging to other parts of the car. These channels are also commonly used in agricultural enclosures, where they can be used to keep livestock and other animals safe from pests and other hazards.

A metal channel can be made from a variety of different materials, but steel is the most popular because it has the best mechanical properties for this type of application. These include hardness, which is the ability to withstand surface indentation and scratches. It is also resistant to friction and erosion caused by oil, water, and steam. This makes it the ideal material for use in many different types of machinery and engineering projects.

A steel channel can be made from a number of different metals, but is usually manufactured through a process known as hot-forming. This involves feeding a metal strip through a series of rollers, which deforms and molds it into the desired shape and size. The final product is usually coated in zinc, which improves the corrosion resistance and durability of the metal. It can also be welded or cut to fit specific applications.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)