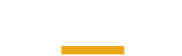

Engineering bolts are incredibly strong and reliable fasteners that can hold much more pressure than other types of fasteners, such as nails or screws. They are often used for construction projects, automotive repairs, and other uses requiring strength and durability. There are many different types of Engineering bolts, and each type is suited to certain applications. Some Engineering bolts have specific material requirements or specifications to ensure they are suitable for the application, and some types of bolts can be customized with additional features, depending on the needs of the project.

Bolts are typically made from some type of metal, such as steel or brass. They can be treated with a variety of methods, including cold drawing and quenching & tempering, to achieve the desired strength and corrosion resistance. They can also be plated with a variety of materials, including nickel, zinc, and chrome to prevent rust or corrosion.

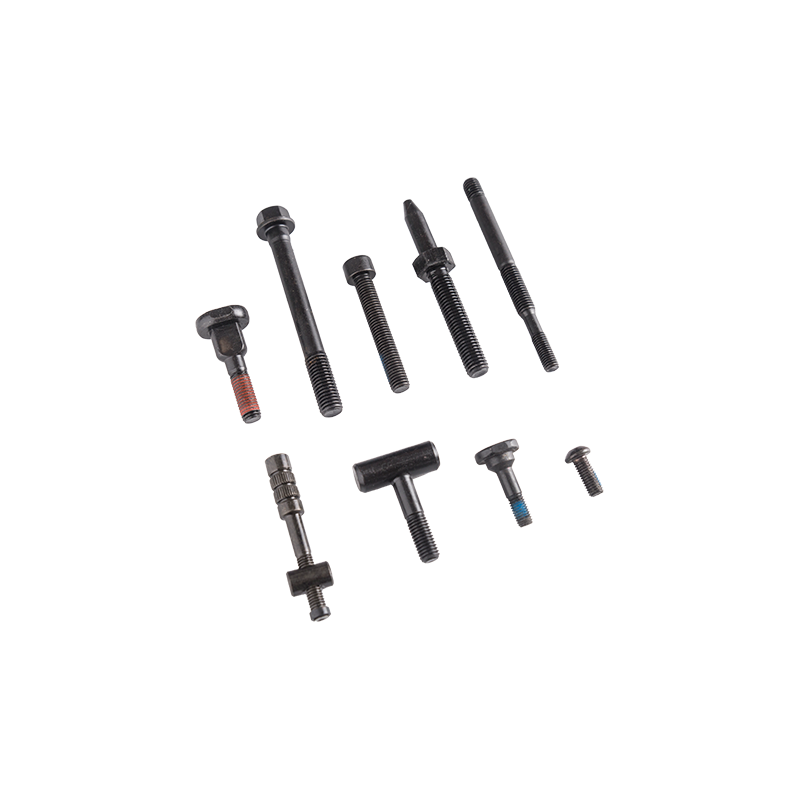

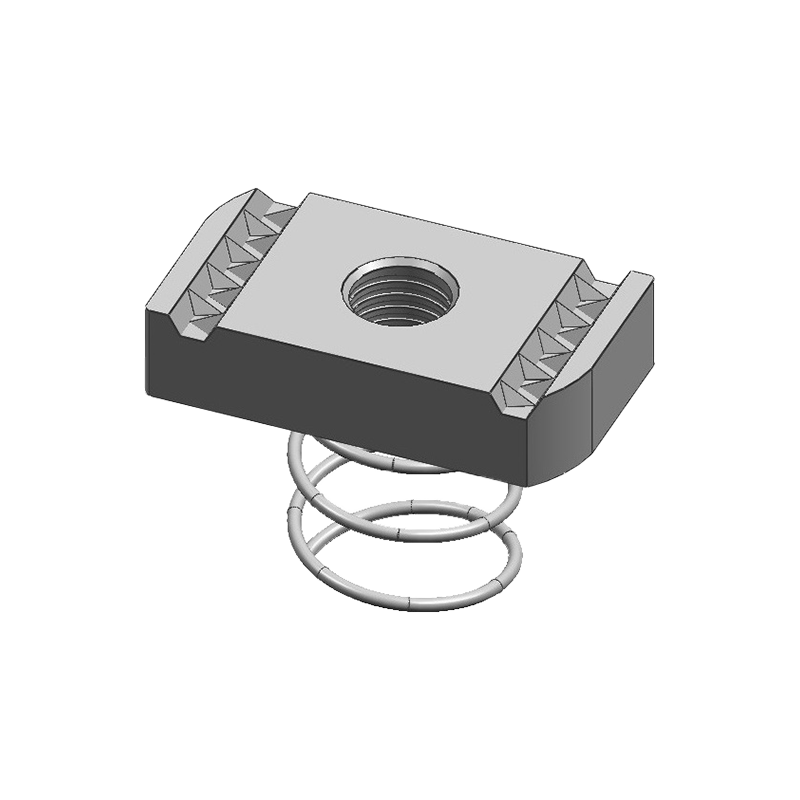

There are also many different types of nuts and washers that can be used with bolts to enhance their performance or protect them from damage. For example, hex nuts can be used to provide a tighter grip on the bolt head than ordinary nuts. Locking devices can also be used to prevent the nut from loosening.

The strength of bolts is usually described by their grade, which takes into account their diameter range, proof load, and minimum yield and tensile strengths. There are also specialized grades for high-strength bolts that are designed to connect structural members, such as steel beams and columns. The American Society for Testing and Materials, or ASTM, sets these standards, which are grouped into seven categories.

There are also other types of bolts that can be used for particular purposes, such as eye bolts. These bolts have a loop on the end of them instead of a head, and they can be used for lifting purposes or to route wires or cables cleanly. Other types of bolts include flange bolts, hex lag screws, and bent bolts.

While bolts are a great option for use in many different applications, there are some drawbacks to using them. For example, they can be more expensive than other types of fasteners and may require specialized tools to install them properly. They can also lose their strength over time if they are not installed correctly. Regardless of these drawbacks, bolts remain a popular choice for construction and other applications where strength and reliability are important. By taking the time to select the right bolt for your project, you can help ensure that it will serve its intended purpose and last for a long time.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)

.png)