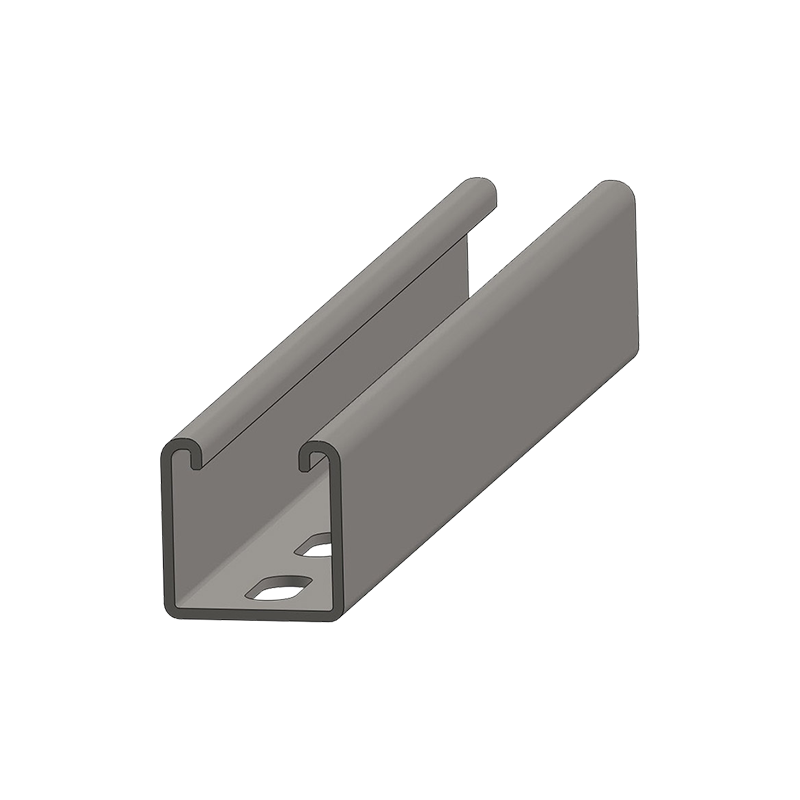

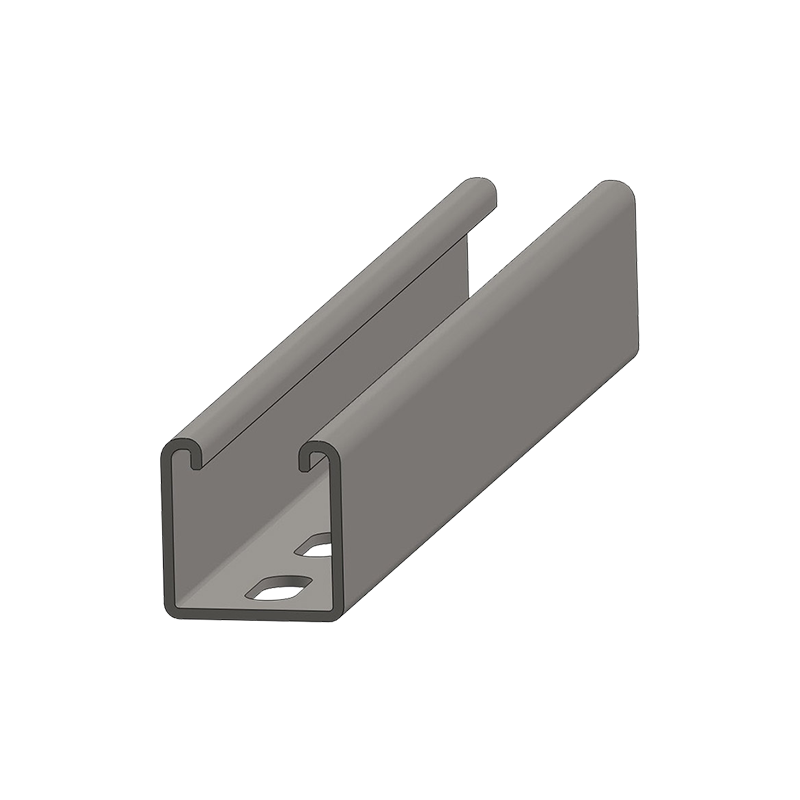

The installation of

channel steel depends on the specific application and the structural requirements of the project. Channel steel is commonly used for providing support and framing in construction, manufacturing, and other industries. Here are some general steps and considerations for installing channel steel:

Design and Planning: Before installation, a structural engineer or designer should determine the appropriate size, type, and spacing of the channel steel members based on the load-bearing requirements of the structure. This includes considering the weight they need to support, the span between supports, and the overall layout.

Preparation: Ensure that the supporting surfaces (e.g., walls, beams, or columns) are properly prepared and leveled. Clear the area of any obstacles that could hinder installation.

Cutting and Fitting: If necessary, cut the channel steel to the desired lengths using appropriate tools (such as a saw or torch). Make sure the cuts are clean and accurate to ensure a secure fit.

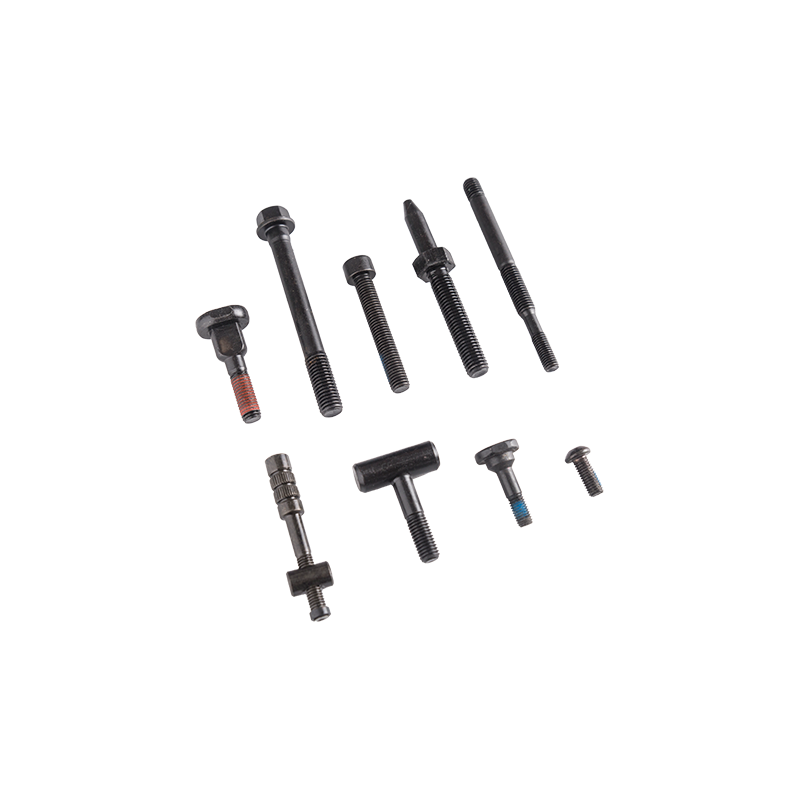

Anchoring and Fastening: Channel steel is typically attached to supporting surfaces using appropriate fasteners, such as bolts, screws, or welding. The method of attachment depends on the type of channel steel, the load it needs to support, and the material of the supporting surface. Follow manufacturer guidelines and engineering recommendations for the correct fasteners and spacing.

Alignment and Leveling: Ensure that the installed channel steel members are properly aligned and level. This is crucial for maintaining the structural integrity of the project. Use leveling tools and measurements to achieve accuracy.

Bracing and Connections: In some cases, diagonal bracing or other reinforcement may be required to provide additional stability. Properly connect adjacent channel steel members to each other and to other structural elements as needed.

Safety Precautions: During installation, follow all relevant safety guidelines, especially if working at heights or using heavy equipment. Use appropriate personal protective equipment (PPE) and take steps to prevent accidents.

Inspections: After installation, conduct thorough inspections to ensure that the channel steel is securely in place, properly aligned, and meets the structural requirements.

Finishing: Depending on the project, additional steps such as painting or coating the channel steel may be necessary for corrosion protection or aesthetics.

It's essential to follow local building codes, industry standards, and the manufacturer's instructions for the specific type of channel steel being used. Proper installation is crucial for the safety and durability of the structure. If you're not experienced with structural installations, it's advisable to consult with a qualified engineer or contractor for guidance.

中文简体

中文简体

English

English

Español

Español

Deutsch

Deutsch

.png)

.png)

.png)